Are you Planning to Build or Renovate your Home? Let’s Talk!

Get Architecture ConsultingGet In Touch

206 Mail Parking Nuages, 14529 Levallois-Perret, France.

Mail: [email protected]

Phone number: +8120-360-4027

Working Time

Monday - Friday: 8.00am - 6.00pm

Saturday:9.00am - 5.30pm

Holiday: Closed

Architectural Models: Enhancing Design Accuracy with 3D Printing in India

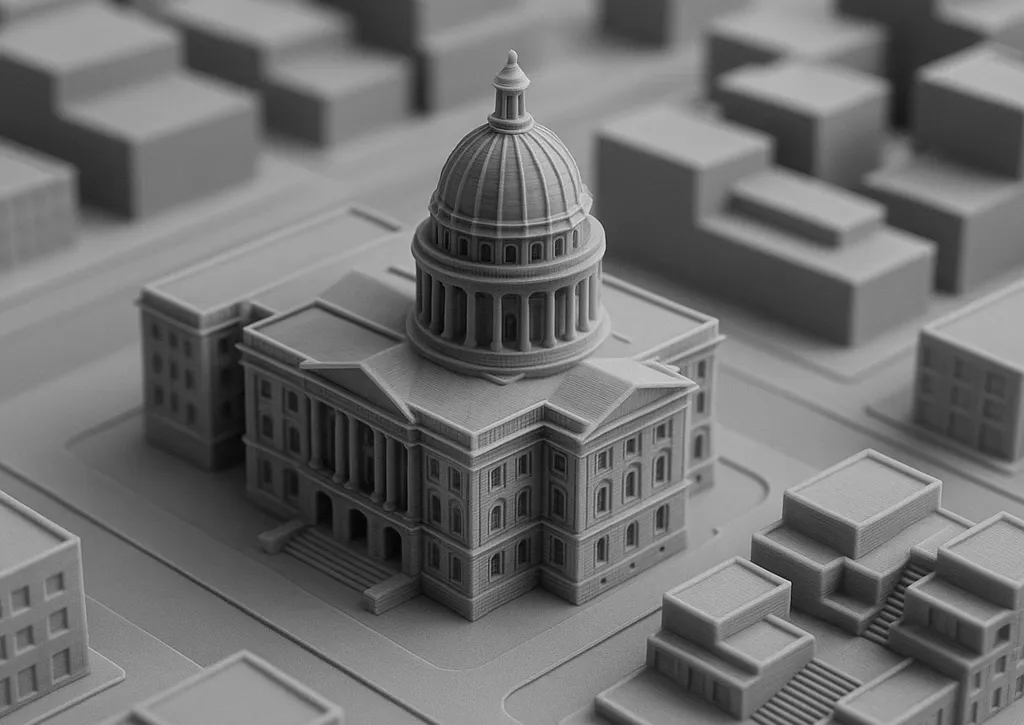

Wait, this entire township model was 3D printed?

That’s the usual reaction we receive when clients first encounter our architectural models. The astonishment is understandable—transitioning from traditional handcrafted models to precise 3D-printed replicas is indeed transformative.

The Evolution of Architectural Model-Making

Historically, architectural models in India were meticulously handcrafted using materials like foam board, cardboard, and wood. Think about those countless hours spent carefully cutting materials, assembling tiny components, and accepting that major design changes often meant starting afresh.

Then came 3D printing, and suddenly everything we knew about architectural model-making transformed completely.

Why 3D Printing is Revolutionary for Indian Architects

I remember when a veteran architect from Mumbai first witnessed our 3D printer creating his residential complex design. “This would have taken my team two weeks,” he remarked, watching as intricate balconies and façade details emerged with perfect symmetry. “And you’ve done it in a day.”

The transformation extends far beyond just speed:

1. Precision That Captures Every Detail

Traditional model-making has inherent limitations with miniature details. Have you ever tried to hand-cut a 1:100 scale jali pattern with dozens of identical openings? It’s practically impossible.

Modern 3D printers can reproduce details down to 0.1mm—think delicate lattice work, ornate temple spires, or intricate façade ornamentation. This level of precision means clients can genuinely visualize even the smallest elements of their future building.

According to a recent project by IIT Madras’s architecture department, this precision has proven particularly valuable for heritage projects where accurate representation of traditional Indian architectural elements is crucial.

2. From Concept to Physical Model at Remarkable Speed

In India’s rapidly developing urban centers, architectural deadlines are increasingly tight—especially when municipal approvals have strict timelines.

With traditional methods, a comprehensive model might take weeks. With 3D printing:

- Complex township development: 1-2 days

- Single building with interior details: Often overnight

- Design iterations: Hours not days

This rapid turnaround means architects can present physical models at more project stages, enhancing client communication throughout the design process.

3. Economical Without Compromising Quality

The economics of model-making have been completely transformed, which is particularly significant in the cost-conscious Indian market. While the initial investment in quality 3D printing equipment is substantial, the cost-per-model drops dramatically over time.

A senior architect from a prominent Delhi firm recently shared with us: “We’ve reduced our model-making expenses by nearly 50% while actually increasing the number of physical models we produce for client presentations.”

The savings come from:

- Reduced labor hours (the printer works while you sleep)

- Minimal material waste (additive rather than subtractive process)

- The ability to print only what’s changed for iterations

4. Material Versatility That Enhances Communication

Remember when all architectural models had that same monochrome look? 3D printing offers a palette of materials that can communicate far more than just form:

- Translucent SLAs for glazing elements that actually transmit light

- Flexible materials for landscape features

- Multiple colors printed simultaneously for better spatial understanding

- Textured finishes that can simulate everything from rough stone to smooth glass

Real-World Applications Transforming Indian Architectural Practice

Context Models With Unprecedented Accuracy

Urban context is everything in Indian architecture. Whether you’re designing in heritage-rich Jaipur or rapidly developing Gurgaon, showing how a building sits within its environment is crucial for planning approval.

Case Study: The Bengaluru Smart City Project

As reported by The Economic Times, when a major mixed-use development was proposed in Bengaluru’s dense urban fabric, planners needed to evaluate its impact carefully. Using advanced 3D printing techniques, the planning committee was able to assess a physical model showing exactly how the development would integrate with surrounding structures.

The planning committee chairman reportedly commented: “This model allowed us to assess the visual impact from angles that digital renderings simply couldn’t show convincingly.”

Sectional Models That Reveal Internal Logic

One of the most powerful applications being developed is the “reveal model”—where buildings can be opened or disassembled to show internal arrangements.

Case Study: Modern Hospital Design

For a leading healthcare facility in Chennai, architects used a sectional model where each floor could be removed, revealing the spatial relationships between treatment areas, circulation, and service spaces. According to Healthcare Architecture Quarterly, during the presentation, stakeholders could physically understand the complex spatial relationships in ways that digital presentations couldn’t convey.

Working Models That Demonstrate Function

Perhaps the most exciting development is the production of working models with functional elements:

- Moving façade screens that demonstrate environmental strategies

- Opening roof elements to show ventilation concepts

- Removable panels revealing system layouts

- Lift mechanisms showing accessible routes

Case Study: Sustainable Design Demonstration

A widely published sustainable office building in Hyderabad utilized a printed model with operable sun-shading devices. As documented in Indian Architect & Builder magazine, the sustainability consultant used it during presentations to physically demonstrate how the building would respond to different solar angles throughout the year.

Making It Work: Implementing 3D Printing in Practice

The technology is compelling, but implementation requires thought. Here’s what we’ve learned from helping numerous Indian architectural practices integrate 3D printing:

1. Aligning Technology With Design Process

The most successful implementations don’t simply replace traditional model-making—they rethink when and how models are used.

An associate at a leading Mumbai practice shared with us: “We now print quick massing models much earlier in the design process. What used to be a presentation tool has become a design tool.”

The best practices we’ve worked with have established clear protocols for:

- Which project milestones warrant comprehensive models

- When to produce exploratory printed models (often small, quick studies)

- How design iterations are managed (typically numbered and archived)

2. The Digital-Physical Workflow

The transition from BIM or CAD models to printable files isn’t always straightforward. Common challenges include:

- Wall thickness issues: What looks perfect on screen may be too thin to print

- Detail translation: Not every digital detail will print successfully at scale

- File optimization: Reducing complexity while preserving essential detail

A computational designer at an emerging practice in Pune developed a clever approach: “We’ve created scripts that automatically prepare our models for printing, thickening walls and reinforcing delicate elements based on the chosen scale.”

3. Selecting the Right Technology

The 3D printing landscape is vast and evolving rapidly. For architectural applications in India, these technologies are most relevant:

FDM (Fused Deposition Modeling)

- Ideal for: Larger massing models, urban contexts, concept models

- Advantages: Cost-effective materials, larger build volumes

- Limitations: Visible layer lines, limited detail

SLA Printing (SLA/MSLA)

- Ideal for: Detailed façades, interior elements, presentation models

- Advantages: Exceptional detail resolution, smooth surfaces

- Limitations: Smaller build volumes, higher material costs

Multi-Material Printing

- Ideal for: Complex presentations with varied materials, transparent elements

- Advantages: Visual clarity, material differentiation

- Limitations: Higher equipment investment, technical complexity

The most versatile practices typically employ a combination of technologies, selecting the right tool for each model’s purpose.

Real Impact: Models That Changed Project Outcomes

The true value of 3D printed models reveals itself in pivotal project moments. Here are examples where printed models genuinely changed outcomes:

The Heritage Conservation Project

As documented by the Indian National Trust for Art and Cultural Heritage (INTACH), a sensitive restoration of a historic structure in Ahmedabad faced skepticism from conservation authorities. Traditional drawings were met with uncertainty at review meetings.

The architects commissioned a detailed site model showing both existing conditions and the proposed interventions, printed in contrasting materials. The model included removable sections showing how new elements would sit within the historic fabric.

According to the project review, having something physical that committee members could examine from all angles completely changed the conversation. The planning application was approved with minimal revisions.

The Township That Found Its Balance

A major township development near Pune had a complex program that was proving difficult to optimize. The developers were struggling to find the right balance between open space, density, and amenities.

As reported in Construction World magazine, the architects quickly printed a series of alternative massing models showing different approaches. During a pivotal meeting, these physical models enabled stakeholders without architectural training to meaningfully participate in complex design decisions.

The project manager noted: “Seeing the physical options helped us prioritize what really mattered. We made informed decisions that improved the project’s marketability while maintaining quality open spaces.”

The Municipal Approval Challenge

A controversial high-rise proposed for a tier-2 city was facing rejection despite meeting technical planning requirements. Local officials had expressed concern about its visual impact.

According to Urban Design India journal, the development team presented a comprehensive city model with the proposed tower as a removable element. During a critical review meeting, this physical model allowed decision-makers to view the proposal from any angle, in proper context.

An official reportedly commented: “I was prepared to reject it, but seeing it properly in its context, I could see how it actually enhanced that part of the city.”

Approval followed shortly after.

Looking Forward: Where Architectural Printing Is Headed in India

The technology continues to evolve rapidly. Here’s what we’re excited about for the near future:

1. Material Innovation

New printable materials are emerging that better simulate actual building materials:

- Ceramics that mimic brick and stone textures

- Translucent materials for glazing elements

- Composite materials for realistic textures

2. Integrated Electronics

We’re beginning to see models with embedded technology:

- LED lighting systems showing internal illumination strategies

- Display elements demonstrating façade concepts

- Sensors that respond to touch and interaction

3. Augmented Reality Integration

Perhaps most exciting is the blending of physical models with digital overlays:

- Energy performance data projected onto physical forms

- Shadow studies animated across printed topography

- Building systems visualized through AR headsets

As reported at the recent Architecture and Building Expo in Bangalore, a project featured QR codes discreetly placed on a physical model that triggered detailed AR explanations when viewed through a tablet.

Practical Advice: Getting Started With Architectural 3D Printing

If you’re an Indian architect considering integrating 3D printing into your practice, here are our recommendations:

1. Begin With Clear Objectives

Define what you want to achieve with 3D printing:

- Faster iteration during design development?

- More compelling client presentations?

- Better planning submissions?

Different goals may suggest different implementation strategies.

2. Consider the Full Workflow

Success requires thinking beyond just the printer:

- Digital modeling standards that support printing

- Post-processing capabilities (cleaning, finishing, painting)

- Storage and transport solutions for delicate models

3. Start With Hybrid Approaches

You don’t need to print everything immediately:

- Begin with printing complex elements for traditionally constructed models

- Experiment with site models while hand-building detailed building elements

- Use printing for rapid design iterations, traditional methods for final presentations

Many practices find this gradual integration more manageable than a complete transition.

4. Partner With Specialists

While in-house capability offers advantages, working with specialist printing bureaus like ours provides:

- Access to multiple technologies without capital investment

- Expert advice on printability and material selection

- Professional finishing services

Most successful practices maintain some in-house capability while outsourcing more complex or larger models.

Beyond Buildings: Unexpected Applications

As architects have grown comfortable with 3D printing, we’ve seen fascinating applications beyond standard building models:

- Tactile models for visually impaired stakeholders allowing them to “feel” designs

- Topographic models for flood risk assessment with remarkable accuracy

- Structural demonstration models showing load paths

- Urban planning tools for community engagement

One particularly notable project involved creating tactile models of a school design for visually impaired stakeholders. As reported in Inclusive Design India, their feedback led to significant improvements in circulation logic that benefited all users.

The Final Word: Models That Matter

In our increasingly digital world, there’s something profoundly important about physical models. They ground abstract concepts in tangible reality.

A senior planning official in Mumbai once told me: “I’ve approved buildings based on perfect digital renders that disappointed me upon completion. But I’ve never been disappointed by a building that I approved based on a good physical model.”

3D printing hasn’t just made model production faster or cheaper—it’s democratized excellence. Practices of all sizes across India can now produce presentation models of extraordinary quality, bringing clarity to complex proposals and giving voice to architectural visions.

In architecture, communication is everything. And sometimes, the difference between a project approved or rejected, beloved or contested, comes down to whether people truly understand what you’re proposing.

In that crucial moment of understanding, there’s still nothing more powerful than placing a perfect physical model on the table and watching as everyone in the room instinctively leans forward to explore it.

Because in that moment, your building already exists—just at a smaller scale.